TL;DR

Television prices plunged as liquid-crystal displays moved from niche to mass production and manufacturers radically cut per-panel costs. Key drivers included much larger 'mother glass' sheets, improved semiconductor-style fabrication, higher yields and automation.

What happened

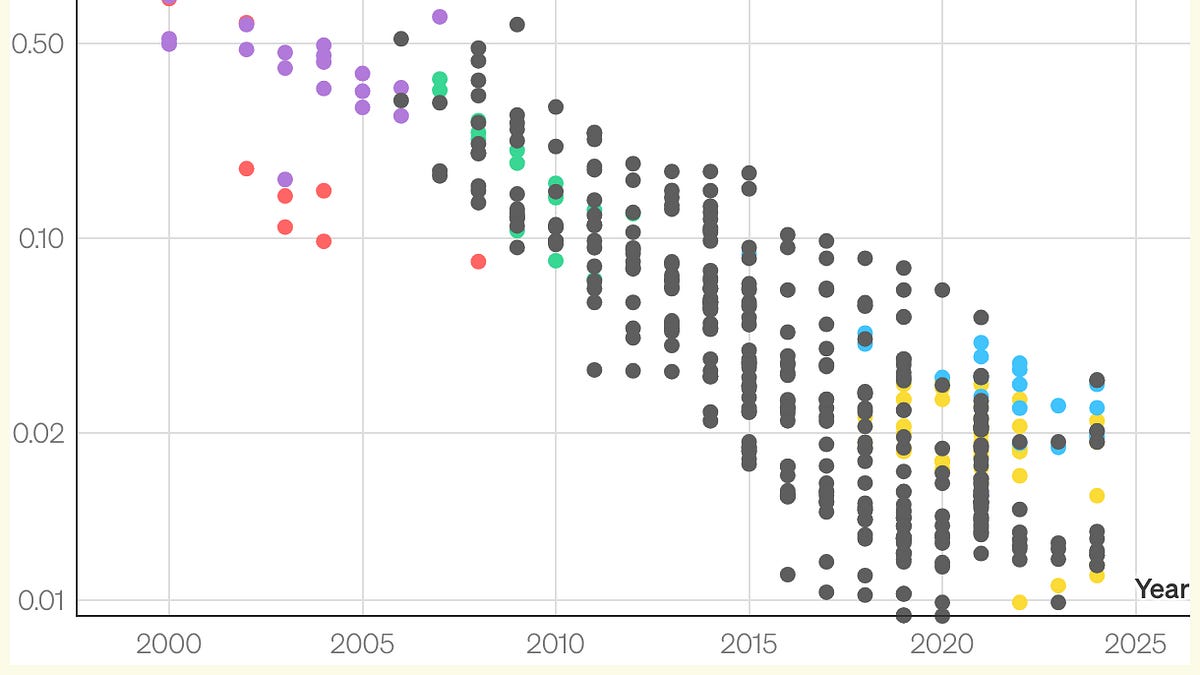

Over the past two decades the retail price of large TVs collapsed even before inflation adjustments. The shift to LCD technology — which went from a small niche in the early 2000s to dominating most sales by the late 2010s — is central to the change. Manufacturers built panels by patterning thin-film transistors onto large sheets of ultra-clear “mother glass,” then cut those sheets into individual displays. Mother glass sizes rose manyfold (from roughly 12×16 inches in early generations to 116×133 inches for Gen 10.5), producing strong geometric cost advantages per unit area. Alongside larger batch sizes, producers introduced faster PECVD equipment, reduced masking steps, improved liquid-crystal filling, adopted cleanroom processes and robotics, and moved to near-continuous flows. Those process improvements lifted yields from roughly 50% in early operations to over 90% in modern fabs, while innovations such as Multi-Model Glass boosted cutting efficiency. The combined effect made big, high-resolution TVs far cheaper for consumers.

Why it matters

- Lower prices made large, high-resolution TVs widely accessible to consumers worldwide.

- The TV case illustrates how scaling batch sizes and factory process improvements can sharply cut costs for complex manufactured goods.

- Manufacturing advances — from larger substrates to automation and yield improvements — are transferable lessons for other display and semiconductor industries.

- The industry’s secrecy and capital intensity shape where cost reductions come from and who captures them.

Key facts

- A 50-inch big-screen TV sold for about $1,100 at Best Buy on Black Friday in 2001; similar sizes can cost under $200 today (as reported).

- A Black Friday 2003 ad listed a 20-inch LCD for $800 and a 27-inch CRT for $150, highlighting early LCD premium pricing.

- Using a metric of dollars per area-pixel, TV prices per area-pixel have fallen by more than 90% over recent decades.

- LCDs represented about 5% of the TV market in 2004 and more than 95% by 2018.

- Mother glass generation sizes grew from roughly 12×16 inches at Gen 1 to about 116×133 inches at Gen 10.5 — nearly a 100-fold area increase.

- Scaling mother glass from Gen 4 to Gen 5 reduced cost per diagonal inch by ~50%; Gen 4 to Gen 8 saw equipment costs per unit area fall by ~80%.

- Process improvements include faster cluster PECVD tools, a reduction in masking steps (from eight down to four), and higher yields (from ~50% to 90%+).

- Manufacturers improved cutting efficiency via techniques like Multi-Model Glass and moved toward continuous single-sheet processing rather than bundled cassettes.

- Modern LCD panels pair liquid crystals with LED backlights and thin-film transistors (TFTs); variants include QLED (quantum-dot-enhanced backlights) and OLED (a different emissive technology).

- Corning and panel makers colocated facilities in some cases to avoid transport issues as mother glass sheets grew larger.

What to watch next

- OLED panels represent a small but increasing share of TV sales and could affect premium-segment pricing and feature competition.

- not confirmed in the source: whether mother glass sizes will continue to expand as the primary cost lever going forward.

- not confirmed in the source: how geopolitical supply-chain shifts or tariffs might change factory location and investment decisions.

Quick glossary

- LCD (liquid-crystal display): A display technology in which liquid crystal molecules rotate polarized light under an electric field to control pixel brightness and color.

- Mother glass: Large sheets of ultra-clear glass used as the substrate on which thin-film transistors and other layers are fabricated before cutting into individual panels.

- Thin-film transistor (TFT): A small semiconductor switch fabricated on the glass that controls the voltage applied to each pixel cell in an LCD.

- PECVD (plasma-enhanced chemical vapor deposition): A method for depositing thin films of semiconductor materials using plasma to enhance chemical reactions at lower temperatures.

- Yield: The fraction of manufactured units that meet quality standards and are sellable; higher yields lower average production cost.

Reader FAQ

What was the main cause of falling TV prices?

The large-scale adoption of LCD manufacturing and dramatic efficiency gains — notably much larger mother glass sheets, better fabrication equipment, fewer process steps and higher yields — drove most of the price decline.

Did panel makers simply use cheaper parts?

Not solely; the source emphasizes scale and process improvements (larger substrates, automation, improved deposition and cutting techniques) rather than only lower-cost components.

Are OLED TVs the new standard and replacing LCDs?

OLED remains a small but growing portion of sales; the source describes it as a rising fraction but does not state it has replaced LCDs.

Will TV prices keep falling?

not confirmed in the source

How Did TVs Get So Cheap? BRIAN POTTER JAN 08, 2026 Share You’ve probably seen this famous graph that breaks out various categories of inflation, showing labor-intensive services getting more…

Sources

- How Did TVs Get So Cheap?

- How Did TVs Become So Cheap? A Brief Look At The …

- Why are TVs cheaper today than they were 10 years ago …

- The Hidden Cost of Cheap TVs

Related posts

- At CES 2026, Keychron’s retro trackball mouse caught my attention

- Smartlet’s dual band lets you wear an Apple Watch and a mechanical watch

- New breath-based glucose sensor in trials brings Apple Watch monitoring closer