TL;DR

Researchers at ETH Zurich developed an electrochemical method that breaks carbon–halogen bonds in long-lived pesticides such as DDT and lindane, converting the halogens into benign inorganic salts and the organic carbon skeleton into usable hydrocarbons. The team built a mobile undivided electrolysis reactor that runs on alternating current, uses DMSO as solvent, and has been tested on contaminated mixtures without pre-treatment.

What happened

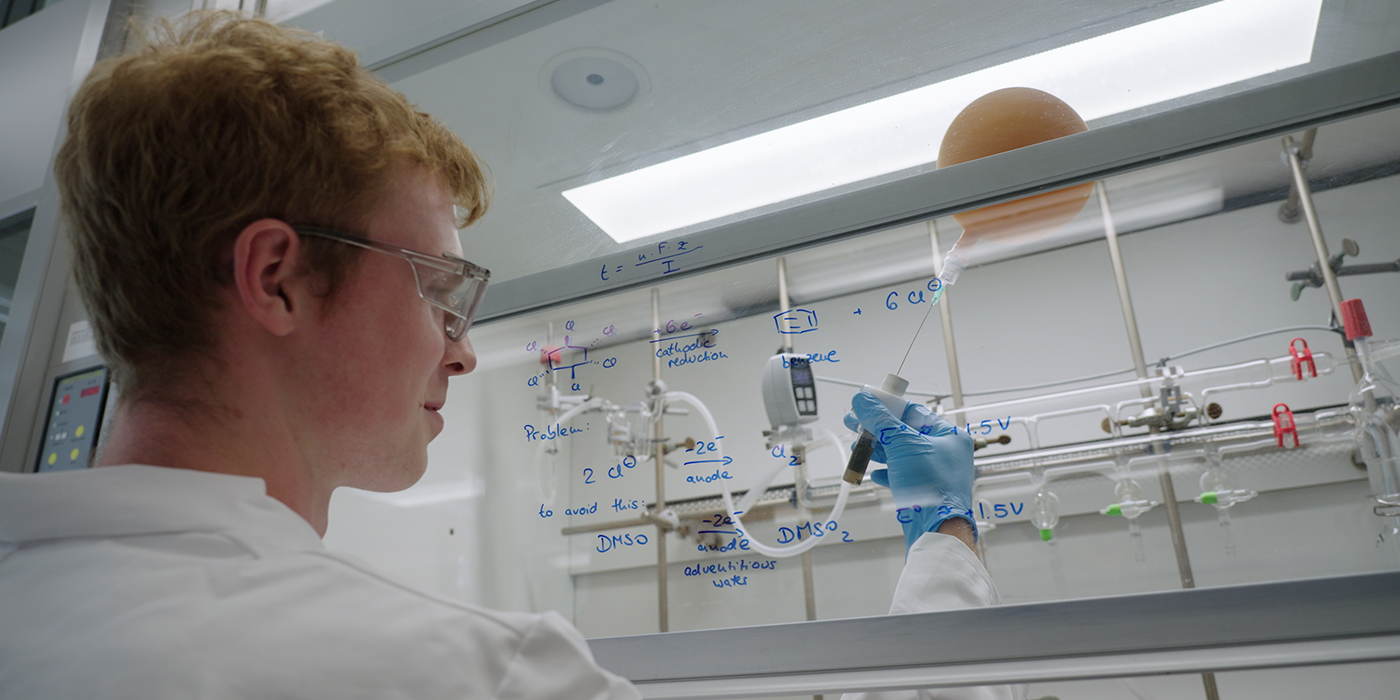

A research team at ETH Zurich, led by Professor Bill Morandi with doctoral student Patrick Domke and former postdoc Alberto Garrido‑Castro, reported an electrochemical process that fully dehalogenates persistent organic pollutants. Using an undivided electrolysis cell and dimethyl sulfoxide (DMSO) as solvent, the method cleaves stable carbon–halogen bonds under mild conditions and supplies electricity as alternating current. That AC waveform reduces electrode wear, suppresses unwanted side reactions (including formation of chlorine gas) and enables the halogen atoms to be sequestered as inert inorganic salts such as sodium chloride. The remaining organic fragments are converted to hydrocarbons — examples cited include benzene, diphenylethane and cyclododecatriene — which are raw materials for chemical industries. The researchers have prototyped a mobile system able to treat contaminated soils or sludge directly, avoiding hazardous transport and enabling on‑site remediation.

Why it matters

- Offers a route to remediate long‑lived pesticides that persist in soils, water and biological tissues.

- Transforms toxic halogenated compounds into inert salts and industrially useful hydrocarbons, supporting circular‑economy goals.

- Mobile, on‑site treatment can reduce the need to move hazardous materials and associated risks.

- Alternating current operation reduces electrode degradation and suppresses dangerous side reactions, improving cost‑effectiveness.

Key facts

- Project led by ETH Zurich’s Bill Morandi; key contributors include Patrick Domke and Alberto Garrido‑Castro.

- Process uses alternating current (AC) in an undivided electrolysis cell.

- Dimethyl sulfoxide (DMSO) is used as the reaction solvent.

- Halogen atoms from pollutants are converted to inorganic salts such as NaCl.

- Organic carbon frameworks are converted into hydrocarbons like benzene, diphenylethane and cyclododecatriene.

- Prototype reactor is mobile and can treat soils or sludge mixtures without pre‑treatment or separation.

- AC operation helps protect electrodes from wear and suppresses formation of chlorine gas.

- Method has been tested on classical pollutants such as lindane and DDT.

What to watch next

- Deployment and field use of mobile on‑site reactors for contaminated landfills, soils and sludge (prototype stage noted).

- not confirmed in the source

- not confirmed in the source

Quick glossary

- Dehalogenation: A chemical reaction that removes halogen atoms (like chlorine) from an organic molecule, often to reduce toxicity or change reactivity.

- Persistent organic pollutants (POPs): Chemically stable organic compounds that resist environmental degradation, can bioaccumulate, and may pose health risks over long periods.

- Electrolysis: A chemical process that uses electrical current to drive non‑spontaneous chemical reactions, commonly used for decomposition or synthesis.

- Alternating current (AC): An electric current that periodically reverses direction; in this context, used to reduce electrode wear and control reaction pathways.

- Dimethyl sulfoxide (DMSO): A polar aprotic solvent often employed in chemical reactions; here it is used as the medium for electrochemical dehalogenation.

Reader FAQ

Which contaminants has the method been tested on?

The prototype has been tested on classic persistent pesticides including lindane and DDT.

Can the system be used on contaminated soil without preprocessing?

Yes; the researchers say soil or sludge mixtures can be treated directly without pre‑treatment or separation.

Does the process release chlorine gas?

According to the team, alternating‑current operation suppresses the formation of poisonous chlorine gas and converts halogens into inorganic salts.

Is the technology commercially available now?

not confirmed in the source

Header Main Navigation Menu en EN DE FR (TA) IT (TA) Electrolysis can solve one of our biggest contamination problems CHEMISTRY INNOVATION & INDUSTRY ETH Zurich researchers have developed a…

Sources

- Electrolysis can solve one of our biggest contamination problems

- Can electrolysis solve one of the biggest contamination …

- Through electrolysis we can neutralize soil contaminants

- Electrolysis Converts Persistent Organic Pollutants into …

Related posts

- How the British Empire Built a Resilient Global Subsea Telegraph Ring

- Enabling PowerVR GPU on RISC-V TH1520: Kernel Plumbing to 3D Rendering

- 2025 Ranks as Second-Hottest Year, Continuing Unexplained Recent Warming