TL;DR

MIT CSAIL researchers built a machine-learning design pipeline that explores unconventional 3D shapes for small underwater gliders, simulating performance and producing 3D-printed prototypes. Two experimental designs outperformed a hand-made torpedo-shaped glider in pool tests and showed close agreement with wind-tunnel predictions.

What happened

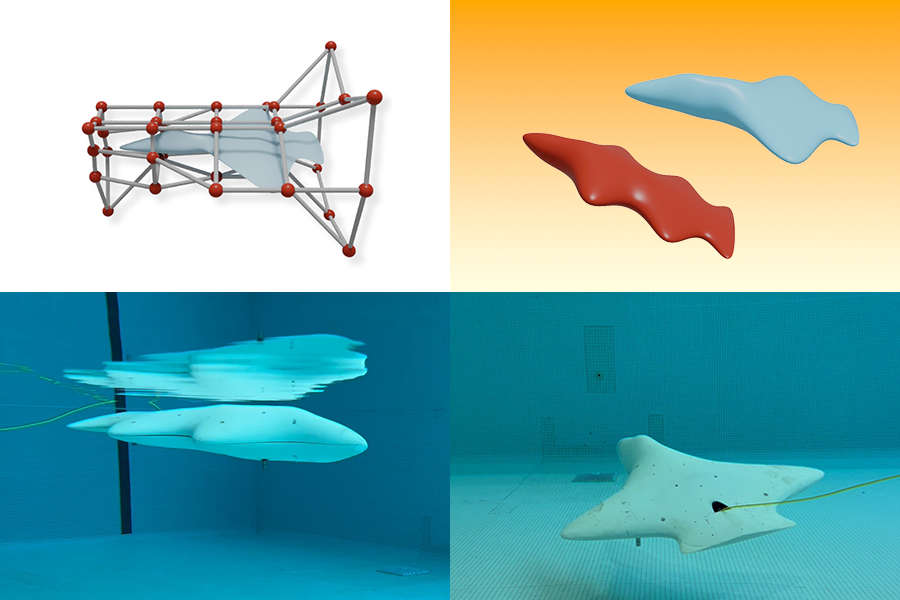

Researchers at MIT CSAIL, working with collaborators at the University of Wisconsin–Madison, created a semi-automated AI design pipeline to discover and optimize glider shapes for underwater use. The team began with more than 20 conventional 3D models — including animals and existing vehicle forms — and wrapped them in so-called deformation cages to generate new variants. They simulated each shape at multiple angles of attack, trained a neural network to predict lift-and-drag behavior, then used those predictions to optimize for higher lift-to-drag ratios. The best-performing designs were exported for 3D printing; researchers produced two bodyboard-sized prototypes (a two-wing and a four-wing configuration). Wind-tunnel trials showed simulation predictions within roughly 5% of measured lift-to-drag, and pool tests found both AI-designed gliders more efficient than a handmade torpedo-shaped comparator. The team reported the work at ICRA and noted plans to close remaining gaps between simulation and real-world performance.

Why it matters

- More efficient gliders could extend mission range and reduce energy use for autonomous ocean monitoring.

- AI-driven shape exploration expands design options beyond traditional torpedo-like vehicles, potentially improving maneuverability and sampling approaches.

- Simulation-guided fabrication shortens the trial-and-error cycle, lowering the cost and material use of prototyping via 3D printing.

- Validated predictions between simulator and experiment increase confidence that virtual design screening can produce viable real-world vehicles.

Key facts

- The pipeline started from over 20 conventional sea-exploration and animal 3D models (e.g., submarines, whales, manta rays, sharks).

- Researchers used deformation cages to create articulated variants of those base models for a diverse dataset.

- Shapes were evaluated across different angles of attack and fed into a neural network trained to predict lift-to-drag performance.

- Two bodyboard-sized prototypes were 3D-printed as hollow shells with internal tubes housing a buoyancy pump, a mass shifter, and electronics.

- Wind-tunnel measurements for a scaled two-wing prototype matched simulation lift-to-drag predictions within about 5% on average.

- Both AI-designed gliders outperformed a handmade torpedo-shaped glider in pool tests by achieving higher lift-to-drag ratios.

- The work was presented at the International Conference on Robotics and Automation (ICRA) in June.

- Research was co-led by MIT researchers Peter Yichen Chen and Niklas Hagemann, with co-authors from MIT and University of Wisconsin–Madison, and supported in part by DARPA and the MIT-GIST Program.

What to watch next

- Researchers working to reduce the remaining gap between simulated predictions and in-water performance.

- Development of glider designs that can react to sudden changes in currents for improved adaptability at sea.

- Efforts to explore and fabricate thinner or more specialized glider shapes and to make the design framework faster and more customizable.

Quick glossary

- Lift-to-drag ratio: A measure of how much upward (or forward) force a body generates compared to the resistance it encounters; higher ratios indicate more efficient gliding.

- Angle of attack: The orientation angle between a moving body and the oncoming flow, which affects lift and drag behavior.

- Deformation cage: A modeling construct that defines control points or regions around a 3D object used to generate articulated or deformed variants.

- Autonomous underwater glider: A low-power robotic vehicle that moves through the water by changing buoyancy or attitude to follow glide paths and collect data.

- 3D printing: An additive manufacturing process that builds physical objects layer by layer from digital designs.

Reader FAQ

Were the AI-designed gliders tested in real-world conditions?

They were validated in a wind tunnel and in pool experiments; open-ocean deployments are not confirmed in the source.

Did the AI create shapes from scratch?

The system started from a corpus of conventional 3D models and generated variants via deformation cages; purely novel-from-scratch generation is not confirmed in the source.

How close were simulations to measured results?

Wind-tunnel lift-to-drag predictions were on average about 5% higher than measured values for a scaled prototype.

Who funded or supported the research?

The project received support, in part, from DARPA and the MIT-GIST Program.

Is the system ready for open-ocean scientific missions?

Not confirmed in the source.

An AI pipeline developed by CSAIL researchers enables unique hydrodynamic designs for bodyboard-sized vehicles that glide underwater and could help scientists gather marine data. Alex Shipps | MIT CSAIL Publication…

Sources

- AI shapes autonomous underwater “gliders”

- AI-Enhanced Automatic Design of Efficient Underwater …

- gliders

Related posts

- PhysicsGen: Simulation-driven pipeline that tailors robot training data

- MIT handheld interface lets users teach robots with three demo modes

- Vision-Only Control: MIT’s Neural Jacobian Fields Teach Robots Self-Models