TL;DR

Researchers at MIT created artificial tendons from tough, flexible hydrogel and attached them to lab-grown muscle to form modular muscle–tendon units. In tests the tendon-equipped system drove a robotic gripper three times faster and generated 30 times more force than a comparable muscle-only design, while improving power-to-weight ratio and durability.

What happened

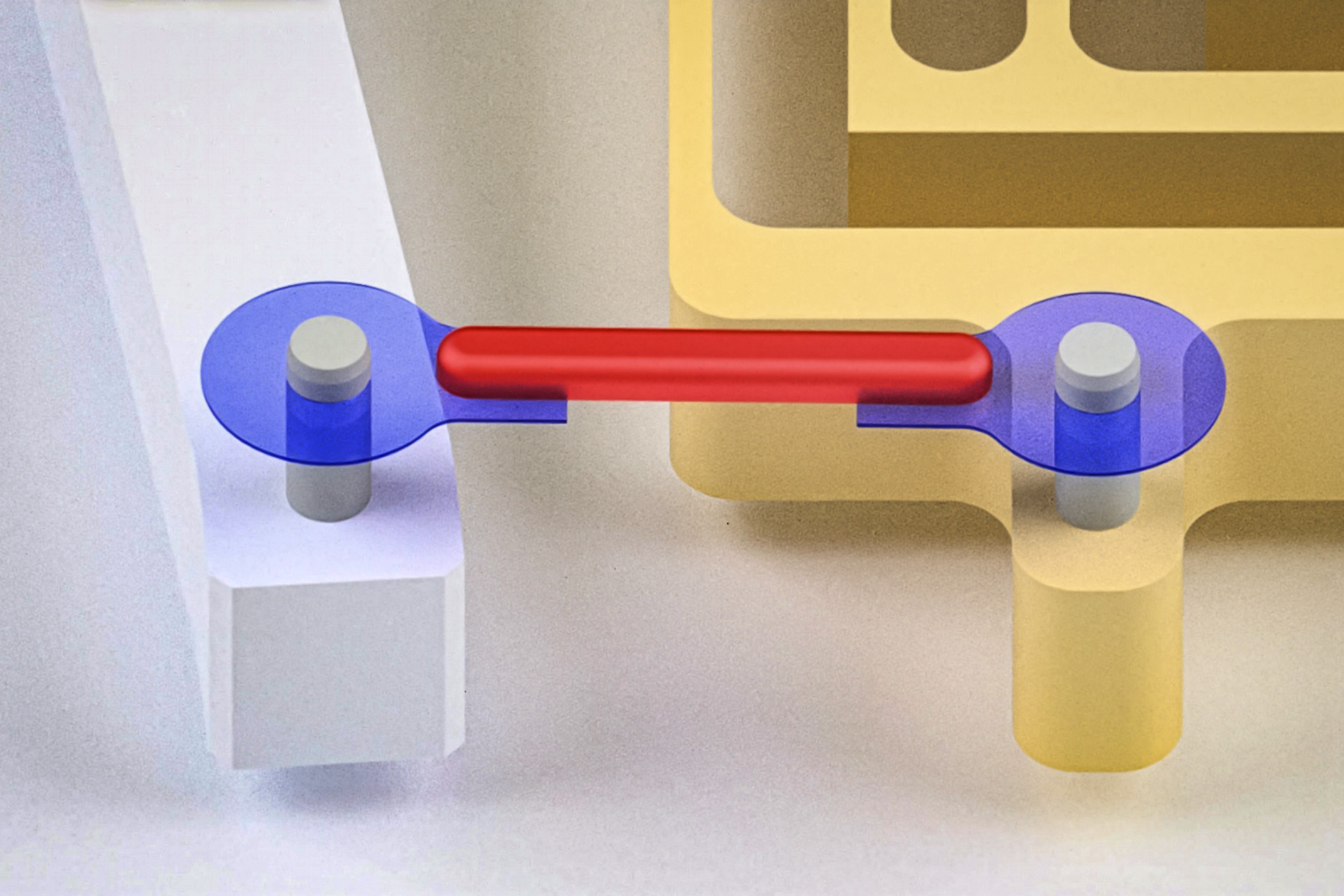

An MIT team led by assistant professor Ritu Raman designed and tested artificial tendons made from a tough, stretchable hydrogel and combined them with samples of lab-grown skeletal muscle to form a modular muscle–tendon unit. The researchers modeled the system as three spring-like elements (muscle, tendons, and skeleton) to select a tendon stiffness, fabricated thin hydrogel cables, and wrapped them around posts on the fingers of a robotic gripper. When the central muscle was optically stimulated to contract, the hydrogel tendons transmitted the force to the gripper, producing faster motion and substantially greater pinch force than a setup that used only a band of muscle tissue. The tendon-based assembly sustained performance over thousands of cycles and raised the system’s power-to-weight ratio, while reducing the amount of muscle required to move the skeleton. The work appears in the journal Advanced Science and was supported in part by the U.S. Army Research Office and the NSF.

Why it matters

- Bridging the mechanical mismatch between soft muscle and rigid structures can let small living actuators move larger synthetic parts more effectively.

- Modular artificial tendons could simplify integration of biological muscle with different robotic skeletons, speeding design iterations.

- Greater force transmission and cycle durability make biohybrid devices more practical for repeated tasks in research settings.

- Improved power-to-weight ratio means less living tissue may be needed for a given task, which could aid miniaturization of biohybrid machines.

Key facts

- The team used a tough, flexible hydrogel as the material for artificial tendons.

- Tendon-equipped muscle gripper moved three times faster than a gripper actuated only by a muscle band.

- The new design produced about 30 times more pinch force compared with the muscle-only configuration.

- Adding artificial tendons increased the robot’s power-to-weight ratio by roughly 11 times.

- Performance was maintained over approximately 7,000 contraction cycles during testing.

- Tendon stiffness was selected using a simple three-spring model representing muscle, tendons, and skeleton.

- Hydrogel samples and recipes were sourced from co-author Xuanhe Zhao’s group at MIT.

- The study is published in Advanced Science and lists Ritu Raman as lead author; additional co-authors include students and faculty from MIT.

What to watch next

- Integration of muscle–tendon units into a wider variety of biohybrid designs to test modularity and scalability (reported as an envisioned use in the study).

- Development of protective, skin-like casings to enable practical, real-world operation of muscle-powered robots (the team is actively pursuing this).

- Wider field deployment or operation outside controlled lab settings: not confirmed in the source

Quick glossary

- Hydrogel: A water-rich, polymer-based gel that can be tailored for toughness and stretch, used here to make flexible artificial tendons.

- Biohybrid robot: A machine that combines living biological tissues, such as muscle, with synthetic structural components to produce movement.

- Actuator: A component that produces motion or force; muscle cells act as biological actuators by contracting.

- Tendon: In biology, a connective tissue that transmits force from muscle to bone; in this study, a synthetic intermediary that bridges soft muscle and rigid skeleton.

- Power-to-weight ratio: A measure of output power relative to system weight; higher values indicate more efficient force production per mass.

Reader FAQ

What material did the researchers use for the artificial tendons?

They used a tough, flexible hydrogel formulation developed within the MIT research groups.

How much did performance improve with artificial tendons?

The tendon-equipped gripper operated about three times faster, produced roughly 30 times more force, and showed an ~11× increase in power-to-weight ratio versus a muscle-only setup.

Are these muscle–tendon units ready for use outside the lab?

Not confirmed in the source; the team is working on protective casings to move toward practical settings, but field deployment is not reported.

How did the team determine the right stiffness for the tendons?

They modeled the system as three spring-like elements—representing the muscle, tendons, and skeleton—to compute a target tendon stiffness before fabricating the hydrogel cables.

The new design from MIT engineers could pump up many biohybrid builds. Jennifer Chu | MIT News Publication Date : December 1, 2025 PRESS INQUIRIES Caption : Researchers have developed…

Sources

- Artificial tendons give muscle-powered robots a boost

- Clip Interesting Engineering real-muscle robots gain …

- Biohybrid Tendons Enhance the Power‐to‐Weight Ratio and …

- MIT Engineers Develop Artificial Tendons to Boost Muscle …

Related posts

- MIT develops control framework to keep soft robots within safe force limits

- MIT engineers design microrobot that flies as fast as a bumblebee

- Jennifer Lewis on 3D-printed soft matter: Octobot to patient-specific tissues