TL;DR

MIT researchers built a handheld, sensor-equipped attachment that enables a collaborative robot to learn tasks via teleoperation, kinesthetic manipulation, or by watching a person perform the task. The team tested the tool with manufacturing volunteers on press-fitting and molding tasks and plans further refinement and testing ahead of an IROS presentation.

What happened

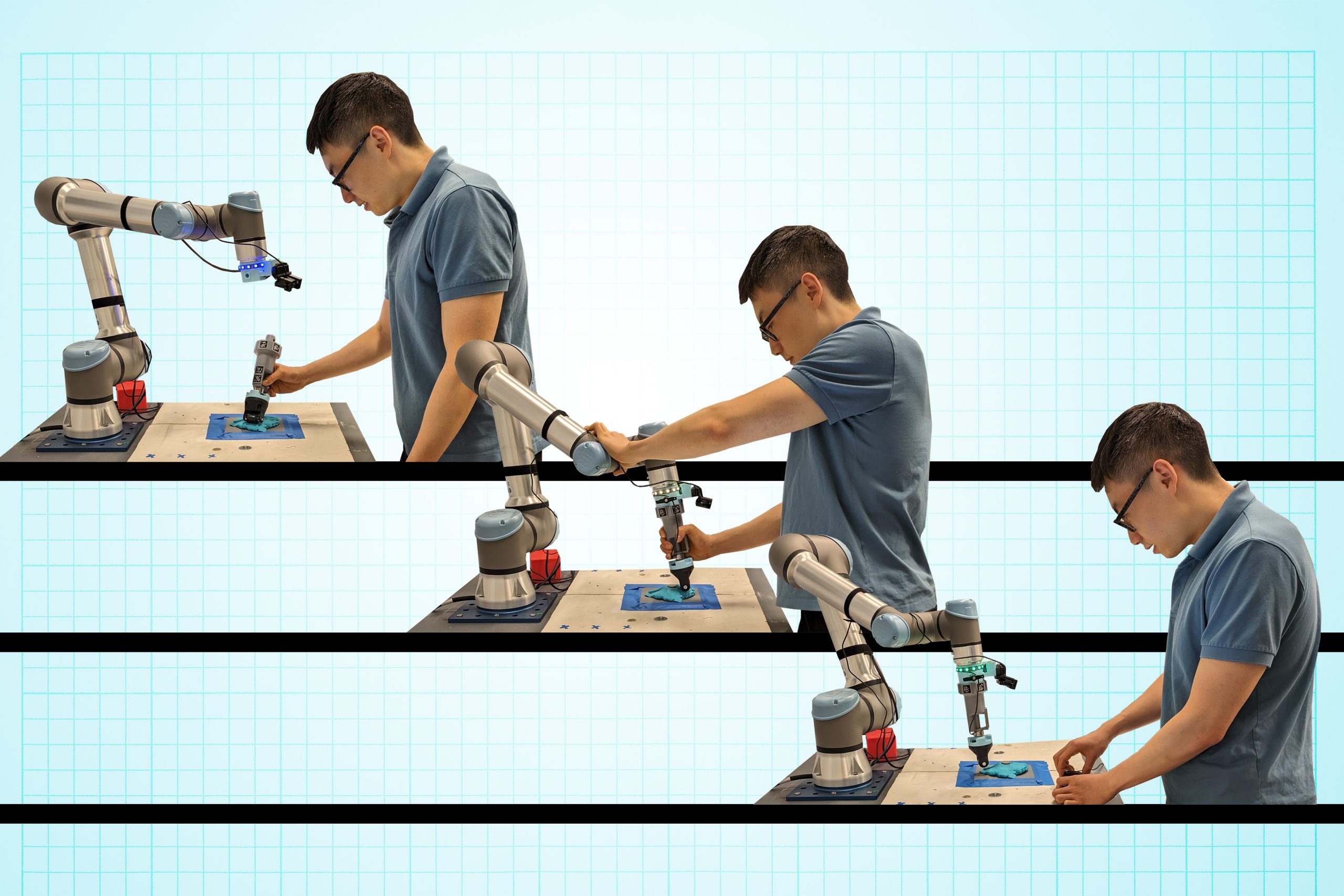

Engineers at MIT created a versatile demonstration interface (VDI): a handheld attachment that mounts on common collaborative robot arms and records motion and forces while enabling three training styles. The device includes a camera, positional markers, and force sensors; it can remain attached to let a user teleoperate or physically move the robot, or be detached so a person can hold it and perform a task while the robot observes. Researchers invited manufacturing experts to an innovation center to train a robot on two factory tasks — press-fitting pegs and rolling a molding material — using each of the three methods (joystick teleoperation, kinesthetic manipulation, and detached natural demonstration). Volunteers generally preferred the natural teaching approach, while noting contexts where teleoperation or kinesthetic methods might be more appropriate. The team will present a paper at IROS in October and intends to refine the attachment and continue testing.

Why it matters

- Expands how robots can be taught: a single interface supports multiple, intuitive demonstration styles for different tasks and users.

- Could lower barriers to robot training by reducing reliance on programming expertise for on-the-job adjustments.

- Offers flexibility for safer training scenarios (e.g., teleoperation for hazardous materials) and delicate tasks (natural teaching).

- May enable broader use of collaborative robots across varied workflows without bespoke reprogramming each time.

Key facts

- The device is called a versatile demonstration interface (VDI) and is a handheld attachment for collaborative robotic arms.

- VDI contains a camera, positional markers for tracking, and force sensors to capture pressure during demonstrations.

- Three supported demonstration modes: teleoperation (remote joystick control), kinesthetic training (physically moving the robot), and natural teaching (holding the detached tool while the robot watches).

- Researchers tested the interface with manufacturing-expert volunteers on two tasks: press-fitting pegs and molding/rolling a rubber-like material.

- Volunteers generally favored the natural demonstration method but identified scenarios where teleoperation or kinesthetic teaching is preferable.

- Paper titled “Versatile Demonstration Interface: Toward More Flexible Robot Demonstration Collection” will be presented at the IEEE IROS conference in October.

- Authors include Mike Hagenow, Dimosthenis Kontogiorgos, Yanwei Wang (PhD '25), and Julie Shah from MIT.

- Work received support from the MIT Postdoctoral Fellowship Program for Engineering Excellence and the Wallenberg Foundation Postdoctoral Research Fellowship.

What to watch next

- Refinements to the VDI design and follow-up studies the team plans to run to evaluate robot learning with the updated tool.

- Presentation and technical details released at the IROS conference in October (paper and results to be shared there).

- Potential expansion of this approach to home or caregiving settings — not confirmed in the source.

Quick glossary

- Learning from Demonstration (LfD): A robot-training approach where a machine acquires a skill by observing or being guided through the task rather than by explicit code-based programming.

- Teleoperation: Remote control of a robot, often using interfaces like joysticks, allowing an operator to maneuver the robot from a distance.

- Kinesthetic training: Teaching a robot by physically moving its arm through the desired motions so it records and replicates those movements.

- Collaborative robotic arm: A robot manipulator designed to work safely alongside humans in shared workspaces, often with sensors and compliant mechanics.

- Force sensors: Sensors that measure applied pressure or force, used to capture contact dynamics during tasks such as pressing or molding.

Reader FAQ

What is the versatile demonstration interface (VDI)?

A handheld attachment for collaborative robot arms that records motion and force data and supports teleoperation, kinesthetic, and natural demonstration teaching modes.

How was the device evaluated?

Manufacturing-expert volunteers used all three demonstration methods to train a collaborative arm on press-fitting and molding tasks at a local innovation center.

Who developed the interface?

Researchers at MIT, including Mike Hagenow, Dimosthenis Kontogiorgos, Yanwei Wang, and Julie Shah, developed the VDI.

Is there a release or commercialization timeline?

not confirmed in the source

MIT engineers designed a versatile interface that allows users to teach robots new skills in intuitive ways. Watch Video Jennifer Chu | MIT News Publication Date : July 17, 2025…

Sources

- New tool gives anyone the ability to train a robot

- MIT Creates Multi-Method Robot Training Tool

- MIT's New Tool Lets Anyone Train a Robot—No Coding …

- MIT Releases Handheld Tool to Train Robots

Related posts

- Vision-Only Control: MIT’s Neural Jacobian Fields Teach Robots Self-Models

- MIT PhD Student Erik Ballesteros Builds Wearable ‘SuperLimbs’ for Astronauts

- MIT symposium explores how generative AI might evolve and be governed